with a grant from the McCune Charitable Foundation

Preface: Dust, Diesel, Decibels and Danger

Introduction

Aggregate and Stone Mining

in New Mexico

State Regulations and

Review

Air Quality

Water Use

Effects

on Rural Communities

Land Use

Protections: County Planning and Review Processes

Mines: Recommendations

Alternatives: Usage of Domestic Waste

Materials for Highway Construction Materials

Glass Material

and Uses in Road Construction

Plastic

Materials and Uses in Road Construction

Recovering

Glass and Plastics in New Mexico

Benefits

of Recycling and Reuse

Program Development

with the Public and Private Sectors

Partnership and Collaboration

Recommendations: Alternative Materials

Contributors / References [including

two reports developed for the RCA

that provided much of the material for this paper]

In the mid-1990s a small gravel sifting operation, located a mile north of the village of Cerrillos NM, was partnered by a much larger gravel operator and renamed Cerrillos Gravel Products. A rock crusher was brought in and soon hundreds of 18 wheel trucks were hauling gravel through the narrow roads of the village.

This heavy industrial traffic completely overwhelmed the peace and quiet of village life,

changing its character overnight from rural to industrial. Dust, diesel, decibels and danger were the "four D's" that dominated what was once a rural village that hoped to attract tourists traveling the nearby National Scenic Byway, the Turquoise Trail.

The roar, jake brakes, and the overwhelming number of speeding heavy trucks traveling back and forth also negatively impacted the Turquoise Trail and the residents living along it. One such resident counted 250 trucks passing in one day. When traveling the road during operating hours it was the norm to find three trucks in front, three trucks behind and one truck passing from the other direction every few minutes. This was too much traffic for the three jobs the mine offered the community. No longer were scenic views possible while riding behind such large vehicles. Many windshields were broken from crushed rock blowing off the trucks, and drivers had to breathe diesel fumes the whole time they were driving the once residential rural highway.

Columns of dust exuded from the gravel pit and could be seen for miles around. Residents located downwind from the pit experienced noise, dust, and diesel fumes inside their homes on a daily basis. Residents in nearby Galisteo found large cracks appearing in their historic homes, and had the same problem with noise, dust, and diesel when trucks from the same operation passed through their village. When citizens petitioned their county commissioners for relief from this poorly sited operation, they found that the county was conflicted by the need for construction materials, but the commissioners did place stipulations on the operation. Not all of these were enforceable and thus the rural residents affected by this heavy industry felt little relief.

In 2000, county commissioners suspended the operation because it was discovered through citizen effort that the operator did not have the water rights required for such an operation, and they had also over-mined the three-acre mine zone by at least ten acres.

Mining companies were meanwhile targeting other major landmarks in the same areas. Citizens found themselves repeatedly having to give thousands of hours of time and equivalent amounts of money to fight off these poorly sited proposals. This involved convincing elected and appointed officials that there are other nourishing values that communities and the state must protect.

While recognizing the need for construction materials, citizens insist that alternatives be sought before we mine away our landscapes so highly valued by New Mexicans and tourists alike. Why not then use the constant river of recyclable materials and at the same time save valuable space at landfills and our invaluable landscape?

Ann Murray, Los Cerrillos, NM, June 2004

This report describes aggregate and stone

mining in New Mexico, identifies environmental and community

effects, and examines the usage of recycled alternative materials

in road construction.

Highways and roads demand enormous amounts of aggregate and stone

materials for their construction. Gravel and other minerals for

road construction are mined from riverbeds and hillsides to serve

the highway construction and building construction industries,

leaving mines un-reclaimed. Local residents and entire communities

feel the affects of industrial traffic and noise, which cause

true public nuisances. Environmental degradation accompanies

mining operations and remains after they cease, with air pollution,

scars on the landscape, and threatened surface waters and groundwater.

Numerous engineers, scientists, and business people have observed and demonstrated that recyclable glass and plastics can be utilized in vast quantities as alternative materials used for highway construction. Highway construction projects utilize natural rock materials: aggregate, crushed rock, base course, sand and gravel. Glass and plastics can substitute for these materials in the surface of paved roads (where asphalt mixes or cement mixes form a hardened surface) and in base courses, where aggregate materials are used. Such alternative materials protect the environment by conserving natural resources, including the lands for mining and landfills. Benefits also include economic development opportunities and reduced pollution hazards, thus protecting human health. Yet only a small percentage of the waste material generated in New Mexico is recycled and made available for reuse. Why? This report attempts to answer the question and suggest realistic alternatives.

Aggregate and Stone Mining in New Mexico

Aggregate, stone, and industrial mineral mines are common across New Mexico. Sand and gravel deposits are located in every county of the state and are mined based on their proximity to the point of final use, quality of the materials in the deposit, and accessibility.

Aggregate and stone mining produces materials that are used in road construction (aggregate, base course, crushed rock, sand and gravel); building construction and landscaping (topsoil, fill dirt, rip rap, scoria, travertine, dimension stone); and other general construction uses. Because haul costs are the single largest variable in determining the cost of material in road construction, aggregate mines are often opened near a specific road project and then abandoned once the project is completed. Consequently, the majority of both active and inactive mines are located along interstate highways or major state and county roads. No data are available regarding the size of disturbed lands caused by the mines, but most operations range in size from one to 20 acres.

New Mexico had more than 165 permitted aggregate and stone mines in 2001, not counting the numerous mines located on tribal lands. (Note that these mines do not include industrial minerals like gypsum, perlite, pumice, and mica.) The demand for new mines seems inevitable with 1.7 billion dollars that the State of New Mexico has marked for highway reconstruction projects.

Existing state environmental laws are limited in scope in regulating aggregate and stone mines. Industrial minerals are covered under the New Mexico Mining Act, which requires formal permitting and reclamation requirements. Aggregate and stone mines are not regulated under the New Mexico Mining Act. They must be registered with the Mining and Minerals Division of the NM Energy, Minerals, and Natural Resources Department, and (except for Bernalillo County, which is regulated by EPA) obtain permits from the Environment Department (NMED) and the Department of Transportation (NMDOT). Portable crusher/screen plants are allowed to operate for up to one year with minimal permitting requirements, and then can move operations to other sites with no requirements for public notification.

Because aggregate and stone mines are exempted from reclamation and regulatory requirements under the New Mexico Mining Act, these mines are not required to re-vegetate or reclaim their operations unless county regulations exist and are applied. Consequently, hundreds of abandoned and inactive mines are located in every county of the state.

The primary environmental impacts from aggregate mineral mines in New Mexico are degraded air quality from excavation and crusher emissions, disturbed lands, and groundwater usage. Some mines also have asphalt or cement mixing plants on their sites, and they are also sources of air pollution.

All but the largest of stone and aggregate mines are considered minor sources of air pollutants and are allowed to emit limited quantities of Total Suspended Particulates, sulfur compounds, nitrogen dioxide, and Volatile Organic Compounds under their air quality permits. These emissions may have detrimental effects on nearby or downwind communities, but the state does not consider these impacts to be significant or to pose serious public health hazards.

Permits from NMED specify the amount of particulate matter or other pollutants a given mill or mine is allowed to emit. Parameters regulated under Ambient Air Quality Standards include total suspended particulates, sulfur compounds, carbon monoxide, and nitrogen dioxide. The state seldom enforces the terms of air quality permits and rarely issues Notices of Violation or fines allowed under the Air Quality Act.

The state's air quality permits require sampling only once every seven days for one 24-hour period, which means that the air quality at a given mine is sampled only 14 percent of the time. The mine is allowed to determine when samples are collected, which means that sampling can be avoided on windy days and done under calm conditions. This sampling by operator discretion allows the permittee to remain in compliance with the air quality permit even though its operation may be violating terms of the permit the majority of the time.

Sand and aggregate materials used in highway construction require the excavation, crushing, and screening of rocks that are predominantly Al-Mg-Fe-silicates, creating dust that irritates the lungs and mucus membranes. According to the American Lung Association, there are links between dust-born pollution and illness and death. A recent ALA study states, "Particle pollution causes a broad range of health problems. Exposure worsens asthma and causes wheezing, coughing, and respiratory irritation in anyone with sensitive airways. It also triggers heart attacks, cardiac arrhythmias (irregular heartbeat) and premature death."

Generally, aggregate and stone mines do not produce materials containing heavy metals or radionuclides. However, aggregate and stone mines are not required by the state to conduct analyses for heavy metals or radionuclides in their permit applications, so no such data have been collected. Because some areas of the Rio Grande Valley contain small deposits of uranium, it would be appropriate to test for radionuclides if there is any indication of uranium mineralization in the deposit to be developed.

Mines are required to wash some materials on site and control dust, using millions of gallons of scarce groundwater to perform these tasks. Although dust control is necessary at these mines, the use of scarce potable water for dust suppression must be weighed against the increasing demands of domestic water use. Although the New Mexico State Engineer's Office is supposed to regulate all groundwater development, most aggregate and stone mines (as well as many industrial mineral mines) develop and use water wells with little or no oversight from the state. Consequently, the actual amount of water used by such mines is unknown.

Residents in the community of Velarde, located in the Rio Grande valley on NM Highway 68, felt effects similar to those described in the preface on Los Cerrillos. Now inactive, two gravel mines has had tremendous impacts on families, especially health and public nuisance effects from small particulates. The mine removed a large portion of a mesa at the north end of town, and then attempted to "stair-step" it, but because it didn't have sufficient property, the slope has been collapsing on the boundary. The State Land Office owns the adjacent property and it sued the operator, Richard Cook. As reported in The New Mexican in 1999, "The site at the northern end of the village, clearly visible from the highway to Taos, is a high, eroded wall of dirt." Though the mines have closed, the impacts continue when the wind blows and the walls slide downward.

Another gravel-mining operation that is still active at El Guique has raised concerns from citizens, San Juan Pueblo, the NM Attorney General, and the US Army Corps of Engineers for issues related to overweight trucks, danger to flood-control dams, destruction of an archeological site, and mining waste in an arroyo. Other types of mines have created negative impacts on local communities; a lack of enforcement by NMED has been a complaint of residents in communities mentioned above, as well as in Picuris Pueblo, Penasco, San Ysdisro, Jemez Pueblo, and Tres Piedras.

The New Mexico Historic Preservation Alliance recently declared Mesa Prieta, an escarpment on the west side of the Rio Grande between San Juan Pueblo and Embudo, a "Most Endangered Site." Areas of the mesa rich in archeological resources dating back 9,000 years have been mined for gravel and stone. The Alliance reports, "Petroglyphs have disappeared and their context destroyed."

Landscape degradation creates non-aesthetic affects. Drivers on I-40 and I-25 crossing New Mexico can see hundreds of abandoned pits and dozens of active aggregate and stone mines. Highly visible and scenic landmarks are considered priceless by New Mexicans as well as visitors. The value of La Bajada Mesa, a geologic landmark located southwest of Santa Fe, has significance to Pueblo peoples and is important to New Mexicans, visitors and the tourism industry. Yet it was once marked for a basalt strip mine. Despite landscape degradation, the mining companies have reclaimed few mines. Some have naturally re-vegetated, but the process is slow.

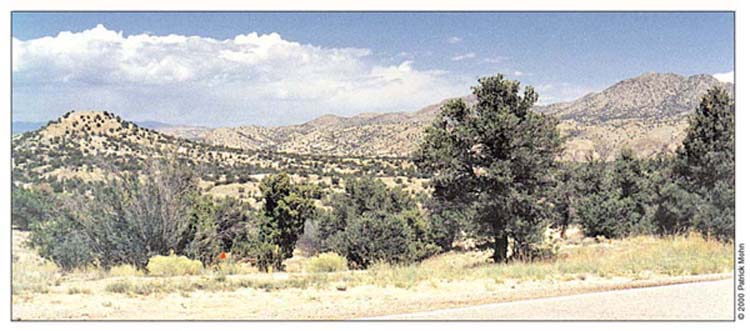

June Morning view to the SW; Photo 2002, RL

Land Use Protections: County Planning and Review Processes

In addition to limited state policies and regulations of sand and aggregate and stone mines, a small number of the 33 counties in New Mexico regulate land use. Most county land use protections in New Mexico are minimal. In a comparative analysis of the land use protections adopted by half of New Mexico's counties, the Rio Grande Chapter of the Sierra Club applauded two of counties for their ordinances that pertain to aggregate mines: Rio Arriba County and San Miguel County. Rio Arriba County's Sand and Gravel Mining Ordinance was adopted in 1999, partly due to the numerous problems at the mines in Velarde.

Eight of the sixteen counties studied have no policies or protections, or, at a minimum, they have a comprehensive plan: Cibola, Colfax, Guadalupe, McKinley, Quay, Sierra, Socorro, and Torrance. Where a comprehensive plan exists, the implementation mechanisms, often in the form of ordinances, are not in place. A few counties recently adopted comprehensive plans and they are in excellent positions to establish standards and review procedures for mining operations, should public health and their rural landscape be community concerns.

Four other counties, Dona Ana, Mora, Sandoval and Valencia, have varying regulatory mechanisms that provide application and review procedures for mining operations. The standards for review compliance, however, are weak or vague, or the review process is confusing, which is not in the public interest. Bernalillo County is similar in that it has a minimal process. Santa Fe County has complex procedures but the results do not measure up to performance standards as established by Rio Arriba or San Miguel counties.

1. Enforce mine and mill air quality permits

through the state's Air Quality Bureau strongly and consistently.

This would require the state to hire more inspectors and make

certain "problem" mines and mills come into compliance

to set an example for all operations.

2. Deny permits to mines that propose locating in areas unsuited

for mining. Mines should not be allowed to operate near Native

American "sacred sites," residential neighborhoods,

historic rural communities, New Mexico Cultural Properties, or

in areas where the resulting "scar" will ruin a scenic

viewshed. Impacts of industrial traffic must be considered in

locating mine sites.

3. Deny operating permits to new operations if inactive or abandoned

mines that are well sited could be re-opened to provide the same

resource. New operations should be permitted only if no other

suitable materials are available in a given area. This would

make better use of existing resources in areas where disturbance

has already occurred and prevent the random and incoherent development

of aggregate and stone mines.

4. Require reclamation at all mine sites. In addition, NMDOT

should require a reclamation plan for all barrow areas created

during highway construction.

5. Change existing regulations and requiring oversight mechanisms

where there are none that can mitigate the effects of aggregate

and stone mines.

Alternatives: Usage of Domestic Waste Materials for Highway Construction Materials

Several state transportation agencies in the US played important roles in the development and utilization of glass and plastic materials during the 1990s. The agencies have written and published specifications for road construction that guide project contractors and local government agencies. New Mexico's Department of Transportation (NMDOT) was not one of the active agencies in these developments, but more recently, it has recognized that it should become a more responsible agency with regard to the environment. In May 2003, Secretary Rhonda Faught signed a commitment to environmental and energy action, calling upon employees to actively engage in nine principles.

Principles numbered one and eight are of particular

interest:

"1. Incorporate sound environmental practices and energy

efficiency throughout the organization, by instilling a culture

of environmental stewardship and energy conservation awareness

at all levels and in all operations;" and

"8. Promote energy efficiency and conservation using innovative

approaches to transportation design, construction, and maintenance

operations, through the use of alternative energy sources for

the Department's fleet of vehicles and through the use of alternative

and recycled materials and innovative construction techniques."

The use of "waste" materials in road construction contributes to needed environmental solutions. The U.S. Environmental Protection Agency indicated that in 2000, only 37 percent of plastic soft drink bottles and 31 percent of glass beverage containers were recycled each year. If a greater demand for recyclable materials from landfills existed for road construction, local governments that operate waste management facilities could divert a greater amount of material from their landfills, find local markets for the materials, and save money on shipping the materials elsewhere.

Glass Material and Uses in Road Construction

Recyclable glass, or cullet, is recovered from glass containers used for food and beverage. The total amount of waste glass material in the US was 12.57 million tons in 2001. The recovery of usable glass from landfill operations was 22 percent, or 2.4 million tons. Glass manufacturers generally use recycled glass. Cullet can also be used as part of the base course of roads and as an additive in asphalt mixes, earning the name of "glassphalt."

Cullet is used in gravel mixes for a base course (Class 5 aggregate) in at least five counties in Minnesota. Rural counties use their locally crushed cullet, thus avoiding transportation costs to move the cullet to a larger site and coping with fluctuations in glass container market prices. Sibley County and Mn/DOT developed documentation that allows for local governments to use up to ten percent cullet in Class 5 aggregate base course. Lab results indicated that the mixed material performs better than standard aggregate in freezing and thawing conditions. Mn/DOT evaluated waste materials in highway construction according to a four-class system. Crushed glass resulting in flat, long articles performed with improved thermal characteristics in a base course and subgrade. It was ranked Class 1 (highest potential for use, requiring a minimum of processing).

NMDOT created a specification for a base course using ten percent glass in October 2003. Working with the NM Recycling Coalition and NMED on the Recycling Task Force, it tested this material on six sites. On one of the sites, Santa Fe County paved the road within the El Dorado Transfer Station, using 30 tons of glass blended with standard base course. The Materials Testing Bureau at NMDOT is monitoring test results, and a specification is expected to be published in NMDOT's manual addendum.

The Clean Washington Center (CWA) describes glassphalt as "asphalt containing glass cullet as an aggregate," and that "glassphalt is basically the same as conventional hot-mix asphalt, except that 5 percent to 40 percent of the rock and/or sand aggregate is replaced by crushed glass." Overall, reports indicate that the glassphalt should contain 10 percent or less glass by weight to safeguard against reductions in skid resistance. CWA states that there is no appreciable difference from asphalt containing 100 percent natural aggregate. Glassphalt has been used by state agencies as well as local communities, including the following.

1. The City of Baltimore, Maryland used glassphalt

during the 1970s when the mayor initiated the revitalization

of its downtown. Glassphalt is durable; streets paved in the

early 70s were outlasting the normal 20-year life of standard

asphalt mix in 2000. The former mayor stated that he would have

paved most of the streets in the city with glassphalt. More recently,

a glassphalt manufacturer sells it for use as an undercoating

on highways.

2. Glassphalt has also been proven in Hennepin County, home of

Minneapolis, Minnesota. The county blended five percent crushed

cullet in a bituminous asphalt wear course on a county road in

1996, and then again in 1997 for its Public Works Center for

both base and binder courses. Mn/DOT has classified the technical

feasibility of glass as a bituminous mix additive as Class 1.

3. Ocean City, Maryland uses glassphalt in a program that

began as a spin off of a mandatory glass-recycling program. The

city collects bottles from all establishments within the city's

limits that hold a liquor license, creating an internal "closed

loop."

4. Allentown, Pennsylvania's Neal Kearn highly recommends the

glassphalt process. During seven years, Allentown used 120,000

tons of "glassphalt" to pave its streets. Allentown

used the Pennsylvania Department of Transportation's specification

of ten percent glass in the asphalt mix. In 1999, Kearn reported,

"Last fall, we held a roundtable of the city's paving gurus

to determine whether to continue with glassphalt or not,"

Kearn says. "It was unanimous to continue with and increase

the program. Our track record speaks for itself." The glassphalt

held up even under the heavy truck traffic entering a municipal

garage facility. The project was discontinued due to a supply

side issue: the glass vendor could not make reliable deliveries.

5. PENN DOT encourages recycling in transportation projects and

has developed a Strategic Recycling Plan with the state's environment

department. In 2000, a DOT district crew laid three mixes provided

by a local asphalt plant along a road: a conventional asphalt

mix, a mix with 5 percent cullet in place of aggregate, and a

mix with 10 percent cullet, using the same machinery.

New Mexico's Recycling Task Force has worked on evaluating glassphalt and glass in a concrete mix. They negotiated on a mix with a local plant, Associated Asphalt, but without success. The concrete mix would have used 3/8" aggregate, but the plant stated that they could not switch between glass for one mix and all natural aggregate in another mix. (Associated Asphalt is a large operator, and it is associated with Richard Cook, owner or operator of many mines in New Mexico.) Whether this is a legitimate processing issue was not confirmed in the documents reviewed for this report. CWA provides a Best Practices document on preparation and placement of asphalt mixes, indicating that glassphalt can be installed using the same equipment and procedures as conventional asphalt.

Plastic Materials and Uses in Road Construction

Six types of resins are used to make plastic products in the US. The resin codes are molded onto the bottom of most plastic containers with a recycling triangle surrounding the number. Nationally, the municipal solid waste stream produced 6.1 million tons of plastics in nondurable goods in 2001. Durable goods containing plastics generated another 8 million tons. Plastics commonly diverted from the waste stream are called PET #1 and HDPE #2. The national recovery rate was nearly 36 percent for PET #1 and 28 percent for HDPE #2. Plastics recovered in New Mexico from the waste stream sources are typically shipped out of state.

Various plastic resins have been demonstrated in plasphalt or as an asphalt cement additive, including a case in New Mexico. Tewa Technology Corp., based in Albuquerque, developed a plasphalt additive product, or aggregate, from all types of plastic materials except LPDE #4, referring to their granulated mix as Treated Recycled Plastic Aggregate. The company closed in 2002 after attempting to demonstrate and test the material with NMDOT. Other demonstrations have occurred in Colorado, Massachusetts, and Pennsylvania. [for more: www.raintreecounty.com/RecyAlte.html#plastic ]

Innovations in infrastructure design and construction often require the support of government agencies, elected officials, entrepreneurs and advocates. Both the private and public sectors are best served if they jointly cooperate in ventures that create highway construction applications for alternative waste materials. Tewa Technology's experiment appears to be the first and possibly the only project utilizing plastic in pavement materials in New Mexico, and it failed. Several causes have been suggested for the company's demise. NMDOT did not conduct other tests in other climate zones of the state, even though it approved the project on an interstate highway. The materials testing firm hired by NMDOT was said not to have enough technical ability to fully evaluate the pavement. Also, NMDOT didn't approve the product for 13 months, more than double the agreed-upon six months. This created financial strains on the firm, since they were unable to sell their product to local governments (and they had stockpiled 100 tons of TRPA, with more plastic material on hand). Also, the highway was paved in November, which is not an appropriate time of year.

Recovering Recyclable Glass and Plastics in New Mexico

According to the NM Environment Department, nearly 2.3 million tons of municipal solid waste (MSW) was generated in 1999-about seven times more than what was recovered. The collection, storage and re-use of waste plastic and glass are in very preliminary stages in New Mexico's communities. NMED reports that the NM Solid Waste Act, adopted in 1990, "established a goal to divert 554,760 tons or 50% of the estimated waste generated in 1990 (the base year), by the year 2000. This goal was not attained in the year 2000. During 1999, New Mexicans reported 290,427 tons of MSW diverted, which is 26% of the estimated MSW generated in the base year or 9.7% of the current waste stream." The bureau did not anticipate a significant increase in diversion rates. In 2002, the total amount diverted from landfills in New Mexico was 156,699 tons, continuing a decline in recovery of waste materials.

Table 1 indicates the variations in recovered glass and plastics year to year. These fluctuations could create a supply side problem if there was a demand for these alternative construction materials, although stronger, more consistent recovery programs could maintain higher and more constant levels of waste recovery. The data for plastics includes PET, HDPE and all other types.

NMED Solid Waste Bureau

| Year | Glass | Plastic |

| 1993 | 3,423 | 460 |

| 1994 | 4,181 | 333 |

| 1995 | 2,223 | 853 |

| 1996 | 1,432 | 252 |

| 1997 | 1,926 | 621 |

| 1998 | 2,587 | 388 |

| 1999 | 3,511 | 425 |

| 2000 | 2,025 | 586 |

| 2001 | 1,808 | 630 |

| 2002 | 1,473 | 656 |

A national study by the American Plastics Council estimates that 200 pounds of glass and 35 pounds of plastics are generated by each household per year. Using these figures, estimates for the state's and four urban counties' generation rates are listed in Table 2. (National average generation rates are appropriate for New Mexico's households, according to NMED's Solid Waste Bureau manager.)

| County / NM | Number of Households | Glass generation @ 200 lbs. per household | Glass generation by ton | Plastic generation @ 35 lbs. per household | Plastic generation by ton |

| Bernalillo County | 220,936 | 44,187,200 | 22,094 | 7,732,760 | 3,866 |

| Dona Ana County | 59,556 | 11,911,200 | 5,956 | 2,084,460 | 1,042 |

| San Juan County | 37,711 | 7,542,200 | 3,771 | 1,319,885 | 660 |

| Santa Fe County | 52,482 | 10,496,400 | 5,248 | 1,836,870 | 660 |

| New Mexico | 677,971 | 135,594,200 | 67,797 | 23,728,985 | 11,864 |

The City of Albuquerque has a glass crusher at its Cerro Colorado landfill. The facility sells the processed glass for 15 dollars a ton to two local vendors who market the cullet at considerable mark-up (selling it for 70 to 75 dollars a ton). The Santa Fe Solid Waste Management Agency operates a glass crusher that produces 1,000 tons of cullet annually.

The US Departments of Defense and Energy are charged with the goal to divert forty percent of their installations' solid waste streams. Cannon Air Force Base, located near Clovis, has diverted glass and plastic since 1999. In fiscal year 2003, ten tons of glass were diverted. The base ceases recovering materials once they have achieved their overall goal, but much more material could be recovered. The base could not find a local use for crushed glass that was processed on site, so it donates the glass to a firm in Lubbock, Texas, paying the shipping costs.

The only plastics that are recycled in waste management facilities in New Mexico are PET #1 and HDPE #2 plastics, a situation considered "tragic" by the New Mexico Recycling Coalition's executive director. For example, Albuquerque processed 285 tons of plastics in 2003, and it sells its plastics to buyers in California, Missouri, and Georgia. Santa Fe estimates that it recovers 200 tons annually and it ships its plastic to Albuquerque for shipping elsewhere. (The 485 tons of plastic generated from the two facilities is only ten percent of the estimated generation of 4,784 tons shown in Table 2.) Cannon Air Force Base diverted four tons of #1 and 2 plastics in 2003, and transported it to McKinley Paper in Albuquerque, along with the base's waste paper.

Diversion of other plastics is limited to Albertson's program, which collects LPDE #4 in the form of plastic bags. The bags are shipped to Phoenix, AZ. A key issue in the provision of construction materials is a reliable supply of the materials, but at this time, New Mexico sends its plastic materials out of state, or landfills them.

Benefits of Recycling and Reuse

There are significant public and fiscal benefits

associated with the use of recycled materials. This is demonstrated

by the City of Albuquerque, which conducted an evaluation of

a program that re-uses asphalt and Portland cement concrete materials

for base course materials, in asphalt concrete, and for subgrade

embankment. The city recognized that recycling road surface materials

allowed it to have a new source of aggregate, thus extending

the life of aggregate and stone mines, extending the life of

the regional landfill, and eliminating costs for processing the

road waste materials at the landfill.

![]() Aggregate

Supplier: Virgin source of pit life extended by 803,687 tons

Aggregate

Supplier: Virgin source of pit life extended by 803,687 tons

![]() Landfill

life extension: 32 ac/yd not used (457,941 cy @ 90 percent compaction)

Landfill

life extension: 32 ac/yd not used (457,941 cy @ 90 percent compaction)

![]() Savings in

Solid Waste costs @ $15.00/ton

Savings in

Solid Waste costs @ $15.00/ton

![]() Total

savings: $12,055,300.00

Total

savings: $12,055,300.00

In addition to cost savings and reduced demand

on landfill space, public benefits of glass and plastic resource

utilization also include:

![]() Reductions

in negative environmental impacts from mining operations, including

noise from trucks and operations at pit, and air pollutants from

the mines and trucks, especially fine particles.

Reductions

in negative environmental impacts from mining operations, including

noise from trucks and operations at pit, and air pollutants from

the mines and trucks, especially fine particles.

![]() Less

conflict over citing new landfills and mines, due to reduced

demand for them.

Less

conflict over citing new landfills and mines, due to reduced

demand for them.

![]() Less

neglect of rural communities. Road construction materials usually

are mined from temporary (1-2 year) sites, but that itself leads

to neglect of the local community, indicated by poor notification

procedures, negligent operators, and unclaimed mining sites.

Less

neglect of rural communities. Road construction materials usually

are mined from temporary (1-2 year) sites, but that itself leads

to neglect of the local community, indicated by poor notification

procedures, negligent operators, and unclaimed mining sites.

![]() Reductions

or elimination of industrial mining traffic in local communities.

Reductions

or elimination of industrial mining traffic in local communities.

![]() Reductions

in costs of vehicle damage in the vicinities of aggregate mines,

due to trucks casting gravel onto windshields and bodies. The

insured public will benefit due to savings from fewer repairs

to windshields and fewer collisions.

Reductions

in costs of vehicle damage in the vicinities of aggregate mines,

due to trucks casting gravel onto windshields and bodies. The

insured public will benefit due to savings from fewer repairs

to windshields and fewer collisions.

![]() Pebbled

glass (cullet) and plastics are benign materials compared to

other sources, thus are not likely to create additional pollution

issues or health impacts when stored or used in road work.

Pebbled

glass (cullet) and plastics are benign materials compared to

other sources, thus are not likely to create additional pollution

issues or health impacts when stored or used in road work.

![]() Preservation

and greater protection of the landscapes of New Mexico, considered

valuable resources culturally, historically, and as long-term

assets contributing to the state's important tourism economy.

Fewer un-reclaimed scars on the landscape would appear, and with

greater recovery of glass and plastic materials, there could

be less litter along the state highways and byways.

Preservation

and greater protection of the landscapes of New Mexico, considered

valuable resources culturally, historically, and as long-term

assets contributing to the state's important tourism economy.

Fewer un-reclaimed scars on the landscape would appear, and with

greater recovery of glass and plastic materials, there could

be less litter along the state highways and byways.

![]() Development

of new business opportunities and jobs.

Development

of new business opportunities and jobs.

![]() Extending

the life of pavements with the use of alternative, effective

materials. Materials such as plasphalt have been shown to exceed

the performance of standard materials, so cost savings also may

occur.

Extending

the life of pavements with the use of alternative, effective

materials. Materials such as plasphalt have been shown to exceed

the performance of standard materials, so cost savings also may

occur.

In a scenario directly related to glass reuse, Santa Fe County could use twice as much glass as what is now recycled throughout the County for road projects. Approximately 20,000 tons of gravel are purchased for County road projects. If the solid waste facility could recover the full amount of domestic glass generated, estimated at 5,248 tons (Table 2), it could reduce its purchases of gravel by the 2,000 tons used for county projects (valued at $38,000) and sell the remaining material to other road construction entities. The facility's recycling coordinator noted in conversation that a business could take the lead in marketing the materials for road projects in the region, thus providing a business opportunity in the private sector.

Program Development with the Public and Private Sectors

States with recycling and market development programs have developed useful information and communication links. Some DOTs not only conducted investigations of waste materials in highway construction products by the early 1990s but also inventoried all waste material sources by town and county, and the uses of those materials. Missouri was considered outstanding for its materials inventory, noting type of storage, estimated annual production and accumulation, and product type rating. In 1996, James Brogan of the University of New Mexico reported that a key problem with NMDOT's recycling program was a lack of communication between NMDOT and local agencies, and suggested that the DOT establish a newsletter. Yet, even today in 2004, its projects such as wood reuse and the specification for cullet in base course are not visible on its website.

Of great importance are state environment agencies, due to their programs regarding recycling, landfill space and out-of-state waste reuse. By 1994, 38 percent of the states mandated recycling. Twenty-three percent indicated that they were out of landfill space or expected to be by 2004, and they were motivated to "close the loop" of recycling and reuse. New Mexico had only a "beneficial use provision," but no mandatory recycling, which is still the case. The Solid Waste Act of 1990 prioritizes waste reduction and recycling, but it was limited in scope, and there was no legislation for use of waste materials by NMSHTD. No doubt, there was great optimism that goals of the act would be achieved without mandates, but as noted previously, only half of the goal was achieved during the course of a decade. A mandatory recycling law for valued materials would be of great consequence in securing a steady supply of materials for reuse within the state.

The Massachusetts Environment Department played an important role in encouraging the reuse of the plastic from trashed computers that were demanding landfill space. The state's bottle bill, passed in 1981 after years of effort, provided a source of funding for entrepreneurial research and development of waste material reuse. For example, Research Engineer Anthony Conigliaro a cold patch product with support from the department, using #3 through #6 waste plastics. The plastics are derived from the plastics in scrapped computers and monitors collected in the Northeast. The cold patch product consists of over 75 percent of plastic regrind material, and is now marketed as Boston's Best Patch. It was found to be cost-effective with other products, and has a lighter weight.

Of the states that researched and/or used glass for road construction by 1994, Connecticut, Iowa, Maine, New York and Vermont had beverage container deposit laws (or bottle bills) in place. Pennsylvania's transportation and environment agencies work together promote the use of recyclable materials, utilizing funds from the state's Recycling Fund to conduct five programs: Research, Specifications, Projects, Outreach, and Contracting.

Local governments, federal installations, tribal governments, and a private corporation operate the waste recovery facilities in New Mexico. Several have indicated their interest in finding markets nearby that can use glass and plastic materials. Recent initiatives, including the NM Economic Development Department program to support small business start-ups and the Governor's sustainable energy program, may indicate that the state is prepared to support innovations in products with recycled materials and link suppliers to markets.

A ready supply of products with recyclable materials is the responsibility of both waste recovery facilities and manufacturing and construction companies, depending on the complexity of the product. Cullet for base course can be provided by local recovery facilities with crushers. In addition, suppliers of construction materials should be readily able to crush cullet to specification for mixing with aggregate.

Innovations in asphalt or cement mixes require research and development, with support from government agencies. Tewa Technology very likely failed in New Mexico due to several obstacles, including slow permitting, reluctant contractors, and NMDOT's failure to conduct promised tests. The owners filed bankruptcy after their test effort and laid off five workers. The New Mexico Business Weekly reported owner Eric Bowers as saying: "We wanted to see New Mexico benefit from being the place where it began. At this point, we're going to have to leave the state and go to a market that is interested in an ecologically sound product like ours." Resistance to change can be a fatal obstacle in New Mexico, whether the resistance is from the government or private businesses with vested interests in the status quo.

As noted previously, NMDOT is committed to principles that may encourage projects using recyclable materials. NMDOT's State Materials Bureau manages the research of new materials and development of road specifications. Their mission is to be "internationally recognized leaders and innovators within the highway construction and maintenance industry in the fields of geotechnical, pavement, and materials engineering." This, in concert with the Secretary's environmental principles, could orient the Bureau toward using local supplies of glass and plastic materials.

The NM Recycling Coalition, composed of staff from waste management facilities in New Mexico, works with NMDOT's State Materials Bureau and NMED on a Recycling Team in a joint effort to use recyclable materials. Other organizations may also provide partnership opportunities. Sustainable Communities/ZERI-NM is a non-government organization that creates environmentally sustainable applications of science and technology.

Recommendations: Alternative Materials

State legislation and regulation influences the development and use of waste materials in road construction. State law can ban landfill disposal of certain wastes, allocate funds for research, development, and entrepreneurial support through its research institutions, and mandate state transportation agencies to investigate or use certain waste materials. The state of New Mexico should develop subsidies, or at the least eliminate barriers, for the use of recycled materials if they are not cost competitive with standard materials. Certainly, if legislation (state-wide and local) helped to create an assured supply of glass and plastic from that generated, and also required straightforward exchanges of materials for road construction projects, efficiencies could be met.

1. Create incentives for greater recovery

rates in New Mexico. Inform the general public of new uses for

their waste materials and promote the environmental stewardship

of waste management facilities involved with reuse programs for

road materials.

2. Strengthen research efforts at NMDOT regarding recyclable

materials that local governments and other entities can provide.

Utilize existing materials testing data from other DOTs, including

PENNDOT, where appropriate. Ensure that evaluative tests of alternative

products and specifications are developed in a timely manner.

Consider specifications for lower-volume roads as opposed to

high-volume roads such as interstate highways.

3. NMDOT and partners should inform the business community and

contractors in all districts, as well as DOT staff engaged in

design and construction projects, of experimental projects, test

results, and specifications for materials using recycled waste

products. For example, the NM Recycling Coalition will participate

with NMDOT on educating DOT district staff during the next year

on the use of wood waste materials. The team should also present

information on the new specification for cullet for base course.

4. The state and partners should develop communications links

that identify ready supplies of alternative waste materials,

road projects with a demand for materials, businesses that prepare

or re-use waste materials in construction products, and transportation/shipping

providers. Include an inventory of the quantities, characteristics

and appropriate end uses of waste materials and products.

5. Alter demand for road construction materials used by NMDOT

and counties by reducing road size or using design alternatives

such as spans rather than fill, especially when scenic roads

are being re-constructed.

6. NMDOT or staff from the legislature or the governor's office

should determine the need for resources to enhance the collaborative

strengths of NMED/NMDOT's Recycling Task Force.

7. Provide resources that strengthen the work of the NM Recycling

Coalition.

Two reports developed for the Rural Conservation Alliance provided much of the material for this paper. They are available upon request, or downloadable at these links:

1) Steven Blodgett, M.S., Center for Science in Public Participation, "Environmental Impacts of Aggregate and Stone Mining in New Mexico," January 2004.

2) Joanne McEntire, M.S., "Recycled Materials: Substitutes for Mining Products Used in Road Construction," June 2004.

Additional material and editorial support

were provided by:

Ann Murray

Julia Fitzsimmons

Ross Lockridge

Their contributions are gratefully acknowledged.

References

American Lung Association, "State of the Air: Health Effects of Ozone and Particle Pollution," 2004, at: www.lungaction.org/reports/sota04_heffects.html#pp.

Aven, Paula, "Stapleton asphalt hits recycling pile," Denver Business Journal, April 21, 2000.

Brogan, James D., A Manual of Good Practice for Recycling/Reuse of Highway Construction Materials," NM State Highway and Transportation Department, 1996.

Brogan citing Barker: Barker, Martin, Recycled Construction Materials Waste Asphalt and Portland Cement Concrete as Base Material, City of Albuquerque, nd.

City of Albuquerque, Solid Waste Department, phone and correspondence, April 2004.

Clean Washington Center (CWA ), Best Practice

in Glass Recycling, November 1996, available at:

http://www.cwc.org/gl_bp/gbp4-0201.htm

.

Clean Washington Center (CWA), Preparation and Placement of Glassphalt, November 1996, available at: http://www.cwc.org/gl_bp/gbp4-0202.htm .

Collins, Robert J. and Ciesielski, Stanley, "Recycling and Use of Waste Materials and By-Products in Highway Construction," NCHRP Synthesis 199, Transportation Research Board, National Research Council, 1994.

Conigliaro, Anthony; Watson, Phil, "Determining the Best Formulation for Unique Asphalt Cold Patch Product Made with #3-7 Rigid Plastic Aggregate," for the Chelsea Center for Recycling and Economic Development, University of Massachusetts Lowell, 2000.

EPA, Office of Solid Waste and Emergency Response, "Municipal Solid Waste in the US: 2001 Facts and Figures," 2003.

Hawley, J.W., "Guidebook to the Rio Grande rift in New Mexico and Colorado," Circular 163, New Mexico Bureau of Mines & Mineral Resources, 1978.

Kearn, Neal, Director of Public Works, Allentown, PA, phone conversation, March, 2004.

New Mexico Historic Preservation Division, "New Mexico's Most Endangered Sites 2004," in Preservation New Mexico, February 2004, p. 4.

New Mexico Mining and Minerals Division, Bureau of Mines & Geology, "Mines, Mills, and Quarries in New Mexico," 2001.

New Mexico Environment Department, Air Quality Bureau Web page, www.nmenv.state.nm.us, 2003

NM Recycling Coalition, Directory, 2002; and phone conversation, Nancy Judd, Executive Director, April 2004.

PENNDOT, correspondence, May, 2004, with Robin Sukley; and "PENNDOT Paves the Way with Glass Pavement," from Strategic Recycling Program website; and "What's Ahead for Recycling in 2002," March, 2002; and "PENNDOT partners with private industry on glass recycling," at: www.dot.state.pa.us.

Rio Arriba County Sand and Gravel Ordinance, (2000-02), p. 9.

Rio Grande Chapter of the Sierra Club, "Comparative Analysis of New Mexico County Land Use Ordinances," 2004

San Miguel County Ordinance, Sand and Gravel Mining Ordinance, (1999), p. 11-13.

Santa Fe County, correspondence and phone

conversation, Justin Stockdale, Recycling Coordinator, April

2004.

Stelmar, Hilary, Potting with Plasphalt, (letter to the editor),

Civil Engineering, August, 1999.

Tarricone, Paul, "Recycled Roads," Civil Engineering, April, 1993.

The Santa Fe New Mexican, "Overweight gravel trucks cited," by Ben Neary, June 24, 1999

The Santa Fe New Mexican, "Scarred Land, erosion prompt complaints," by Ben Neary, August 29, 1999.

University of Minnesota Technology Transfer Program, (Reprinted from The Resource, Minnesota Office of Environmental Assistance, spring 1998), [WAS] at: www.cts.umn.edu/T2/archive/mixedglass.htm.

~

PO Box 245

Cerrillos, NM 87010

murlock@raintreecounty.com